Class A Headphone Amplifier

This began life in around 2012, designed to drive a pair of Sennheiser HD650 open back headphones. The first version was based on a rats nest of veroboard, powered from a mains transformer salvaged from an old B/W TV and lived in a shoe box which I used to take to work every day, part of my job survival kit intended to drown out the office radio.

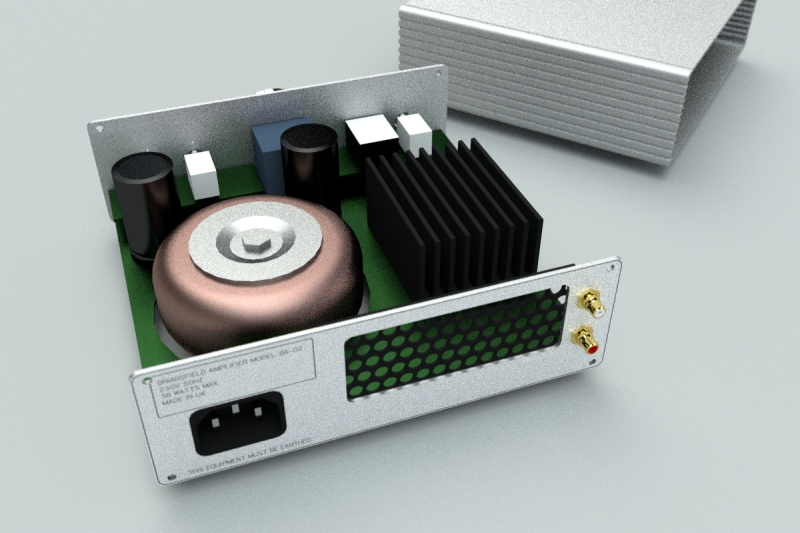

The first product render from late 2013

The first product render from late 2013 Old Solidworks render from 2013 showing initial envisaged layout

Old Solidworks render from 2013 showing initial envisaged layout 2016 CAD version

2016 CAD version Assembling the prototype

Assembling the prototype Prototype after branding

Prototype after brandingOver the next few months it evolved into an improved design and the makings of an idea for an end product, eventually becoming my first Briarsfield branded product design. The selling point of the design became an amplifier which was fully D.C. coupled via a servo circuit (there's not a single capacitor in the signal line), so will amplify right down to D.C. with virtually zero attenuation or phase shift. Variable gain (via reed relays - I worked as a test engineer for a reed relay manufacturer at the time this was conceived) crept in, as did a combined comparator-based fault protection and on-off mute circuit.

The design lingered on in rat's nest form for another couple of years, until 2016 when with student access to Autodesk's Inventor I resolved to make it into a functional product prototype.

The design was re-worked, with the various tweaks incorporated and turned into a workable PCB design. The decision was made to separate both channels as far as possible, with dual miniature toroidal power transformers and with each channel contained on its own PCB, stacked vertically in order to make the most of the enclosure volume available.

Space was tight, but with some fine tuning everything was fitted in to the small enclosure. Although I'd done a lot of work in 3D design before, this was the first time I attempted to develop a design entirely via CAD/CAM; the circuit design was analysed and qualified in SPICE, all components were modelled in Inventor and the design assembled virtually, moving elements around until everything fitted together correctly.

The resulting assembly even generated accurate cutting templates (I had just invested in a small CNC machine).

I was lucky enough to be loaned a Radford distortion meter and spectrum analyzer; distortion performance was quite good at less than 0.001%, probably lost below the noise floor of the old test kit; frequency response was broad and flat, with less than 0.2dB ripple between 5Hz-20kHz with a bandwidth of around 250kHz. Add to this a power output reserve of around 1W with over 8V RMS of voltage swing, it has enough reserve to drive most headphones (it drives my 650Ω Beyerdynamics better than my Schitt Valhalla does).

The downside is that the Class-A design necessitates that the amplifier's internal bias chain has to be a lower resistance than the load connected (otherwise negative edge clipping creeps in, the fabled 50% efficiency limit). I decided on 100Ohms as the lower impedance limit so that I could drive my lowest impedance Sennheisers, yet still wanted enough voltage swing to drive higher impedance cans such as the Beyers - conflicting requirements. As a result, it's inefficient and runs hot (hey, that's the M-O of Class A), but sounds good.

The future? There are designs for a Mk2, this time with some soft button microprocessor control and dynamic headphone matching as an attempt to increase efficiency and a further revised circuit.