Listen Again Microphone Pre-amplifier

This was a side project designed for the university in around 2016. Nowadays lectures are captured to allow students to listen to them later (hence 'Listen Again'). Most teaching rooms use microphones which require phantom power and at the time around campus there were various configurations of microphone pre-amplifiers, PC audio converters and phantom power injection boxes, depending on the room and the equipment it contained.

Prototype front view

Prototype front view Prototype rear view

Prototype rear view Prototype cutaway

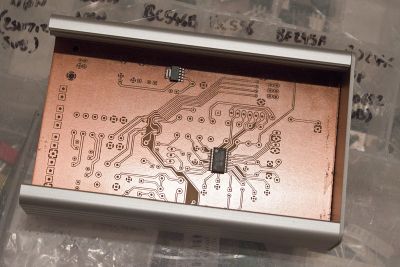

Prototype cutaway Building the prototype PCB

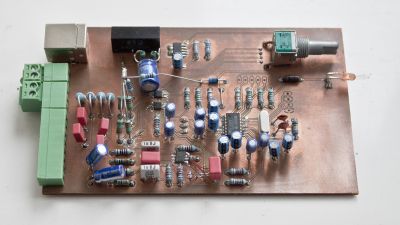

Building the prototype PCB Test-worn prototype PCB

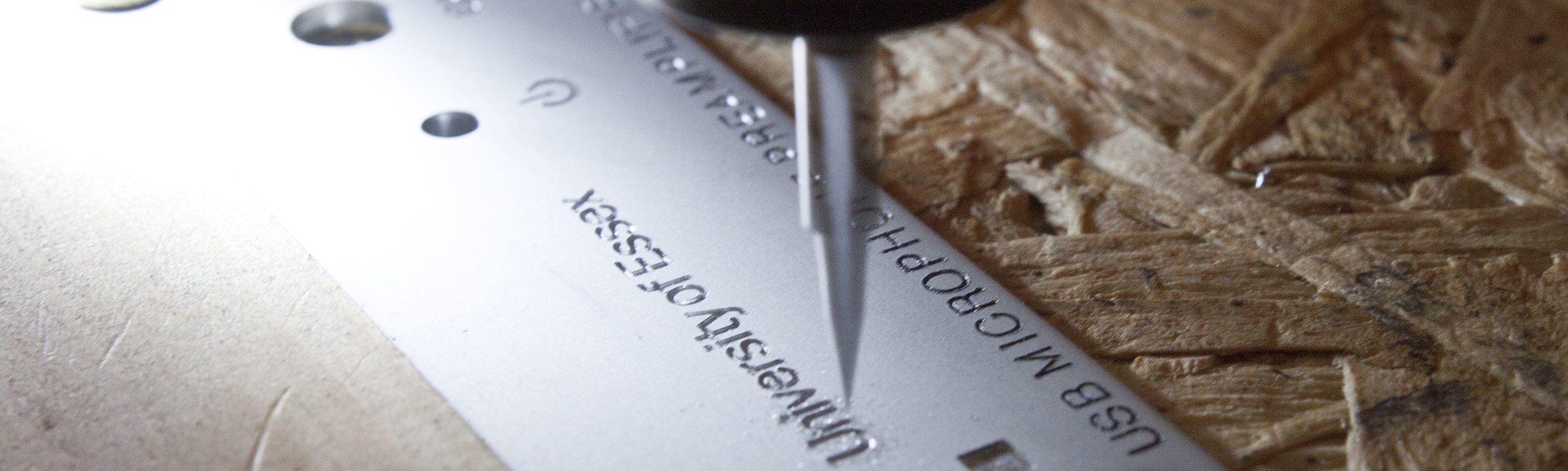

Test-worn prototype PCB Engraving the front panel

Engraving the front panelThis solution almost always required several devices to suitably process the microphone, inject the required power and input it to the room’s PC for capture, and in many cases the resulting performance and reliability was less than ideal. My solution was a discrete ‘one box’ unit to both power and record the microphone and process it to the PC in PCM format. The target was to deliver something which was both cost effective, minimal in size and which had a minimum of user-settable controls, i.e. just gain and configurable inputs to support a broad range of microphones.

A few options were included, such as jumpers to switch between mono/stereo input and enable P48 phantom power, and a line audio output for convenience. Power would be derived from USB (another disadvantage to the units we had been using, most requiring their own power supplies), and the device would need to allow driverless ‘plug and play’ installation on our teaching PCs.

Armed with KiCad, I developed a small, 2 layer board design which was small enough to fit inside an inexpensive aluminium enclosure. To keep cost to a minimum, the configuration jumpers and all connections aside from the USB were of the industry standard Phoenix format, allowing bare wire connections to be made with a screwdriver during installation. I based the unit around one of Texas Instruments' PCM Codec devices, adding a balanced stereo audio mic stage with gain variable between 10-25dB, audio line output stage and 48v voltage booster for the phantom power.

For ease of modification, the prototype device was built using through hole components where possible, with the intention to move toward surface mount for production. I developed the prototype PCB at home and milled the enclosure and engraved the graphics using my miniature CNC machine; I trialed engraving as a proof of concept, the result is good but a slow process and therefore unsuitable for production use. My intention for production would be to have the enclosures machined and silk screened by the manufacturer. I made some tweaks to the PCB during development and the resulting performance was good with a broadly flat frequency response, good noise floor and when compared side-by-side with our existing system, equal or better subjective audio quality.

Revision 2 exists, at least in CAD, using SMD components with the resulting smaller PCB, with the modifications incorporated but the rest of the design mostly unchanged with the exception of an extra indicator light to show the presence of audio at the input and output of the device, to ease troubleshooting during room maintenance.

During the time it took the cogs to turn for the university to show interest and give me the justification to invest more time and money into a viable production version of the unit, their roadmap had been changed to incorporate lecture capture into Dante audio over IP (networked media transmission is something which many universities are moving towards and has been the subject of a couple of reports which I've written), meaning that this is now unlikely to see widespread use. I have considered adding some form of DSP to the unit to allow basic functionality such as frequency tailoring and ducking, but this would add considerable cost and development overhead.