Study Pod Connectivity Hub

For the past four years while studying, I've worked for the university's AV team. My job role is fluid; I do much of the bespoke graphical and CAD design we use in teaching spaces across campus, in addition to designing and building custom electronic hardware.

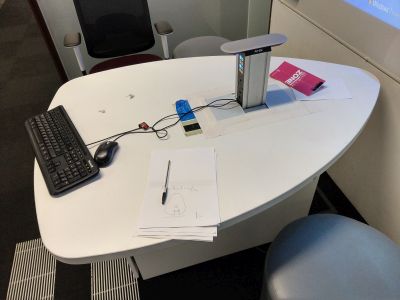

What we started with - the (broken) tower on the desk

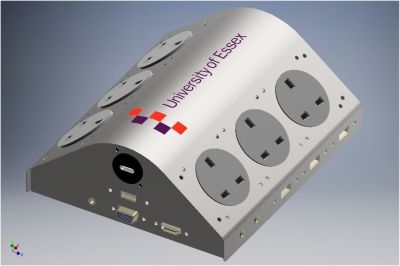

What we started with - the (broken) tower on the desk Initial Inventor CAD design

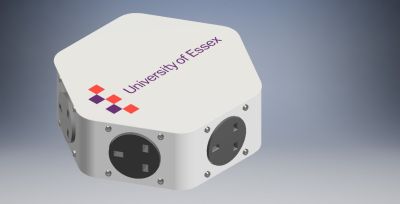

Initial Inventor CAD design The 'other' design

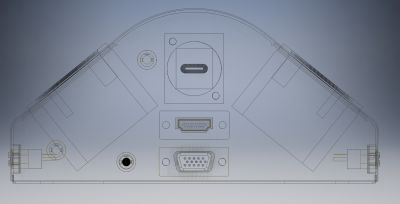

The 'other' design End-on wireframe view showing packaging

End-on wireframe view showing packaging Assembling the prototype

Assembling the prototype Mock-up to create fitting template

Mock-up to create fitting template Production unit (1)

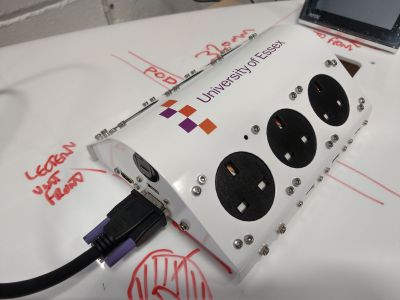

Production unit (1) Production unit (2)

Production unit (2) CAD designed equipment rack

CAD designed equipment rackI create a fair amount of designs, ranging from mundane stuff like faceplates and floor boxes, ranging to the more interesting - designs which form a large part of end products. Luckily I managed to strike up a partnership for design fabrication to an engineering company who we buy a lot of network hardware from, and apart from the occasional minor glitch, the quality of what they make for us is good.

A couple of years back I became involved with a refit project for the group study area in our main student centre. Initially the study pods were fitted with commercially sourced retractable units, but these proved to be fragile and after just over 2 years of use many were failing.

Small footprint was an important consideration in our requirement, the unit intended to be positioned as far back on the desk as possible to maximize usable surface area; this ruled out most readily available products.

Initially we had an established company design us a replacement, but what they offered was inflexible and expensive - it didn't give the all of connectivity we required and was nearing £1,000 per unit. Additionally, although the individual parts of their design were replaceable (these were being fitted in a busy space, things get broken), design of the unit made any kind of maintenance extremely difficult.

Armed with Autodesk Inventor and some initial skepticism from my manager (you want to do what?), I was certain I could design something better and over the space of a few hours I roughed up two alternate hub unit design proposals in the form of flat sheet metal designs, designed to house readily available sockets and hardware.

After submitting both proposals to the manufacturer for costing and some discussion based around the cosmetics and features of each design, one was chosen based on overall cost and footprint on the desk surface and a prototype unit was manufactured. After some minor alterations to the design and some positive user feedback - at the time of writing, these have been installed for over a year without fault and the university now wants to install them in other areas - a batch order was submitted with the production units delivered as an empty shell and populated in house. For a finishing touch, I added university branding and some labels, sending these to the manufacturer in the form of vector images for silk screening.

The resulting total unit cost of the design was well under 50% of the equivalent commercially available unit that we were considering, helped from the use of off the shelf hardware and the in-house design.

The CAD drawings show how space-efficient the design is; despite the compact packaging, assembly is quick and straightforward as the unit separates into two sections. The same goes for maintenance; once the top section is removed all parts are readily accessible, making repair simple. Being manufactured from 1.2mm steel with rounded profile edges the units are also more resistant to accidental damage and vandalism than many of the commercial designs we were considering.

I did some extra design work as part of the project - a custom miniature equipment rack unit designed to slot into the existing pod's cabinet, and a wraparound heavy duty moulded worktop to replace the chipped laminate.