Briarsfield Audio Designs

Briarsfield is an umbrella of sorts so that I can tie my designs together with a particular look or design ethos. The name came about around 15 years ago, I used it on my old website and from there a theme emerged - sparse black on white with Classical style font - I thought it looked elegant (I still think the website has aged well, considering it's over a decade old). Various manufacturers have used Classical style fonts on their products, Audio Analogue and Technics to name two, so I don't think it's a bad design choice.

Model 01 Loudspeakers

Model 01 Loudspeakers Model 01 Power amplifier

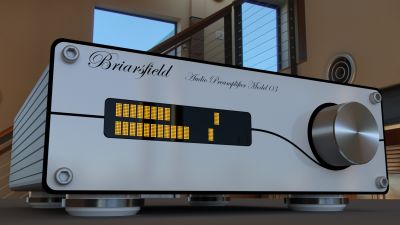

Model 01 Power amplifier Model 01 Preamplifier

Model 01 Preamplifier Model 01 CD

Model 01 CD Model 01 Headphone Amplifier

Model 01 Headphone Amplifier Model 02 Preamplifier

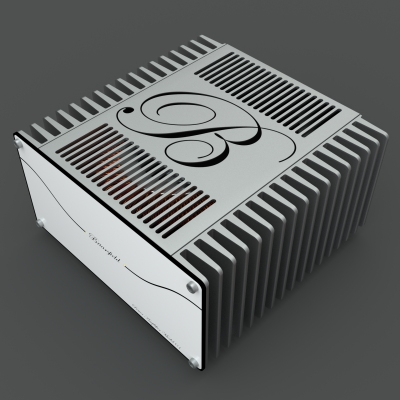

Model 02 Preamplifier Model 03 Preamplifier

Model 03 PreamplifierBriarsfield is a concept brand, and exists as a hobby and a vehicle to test design ideas, a creative outlet. I love designing products, I like designs which cram a lot of functionality into a small space and do it elegantly - compact and smart. Since I was a kid I've been fascinated with taking things apart to see how they were made and learning what was behind the 'smoke and mirrors'. Product design is just the analog of that.

I like products which have a deceptive size or format; looking at one of the renders where there is no sign of scale, the Briarsfield products appear larger than they actually are, maybe near the size of a regular audio separate. In fact, they're tiny - a footprint of roughly 150mm (6in) square. Large, miniature audio separates.

I've designed and built a lot of audio gear over the years (about half of what I currently use is home brew to some extent). I've branded various home brew stuff as Briarsfield, but wouldn't count many of them as a unique design; for example, I run a passive pre in one system, and run a couple of active crossovers, but I wouldn't claim anything novel about, for example, a set of Sallen-Key Linkwitz crossovers, even if I designed the PCBs myself.

Anything I design with the brand in mind has at least one distinct novel feature. All of them use off-the-shelf parts where possible. Every custom part is designed in CAD (I use Inventor and Eagle, Blender for rendering and fine tuning), with machining as simple as possible (i.e. something which I could conceivably do on my own 3-axis CNC machine or a mainstream FDM or resin 3D printer). My intention always is to eventually build a working prototype of everything I design.